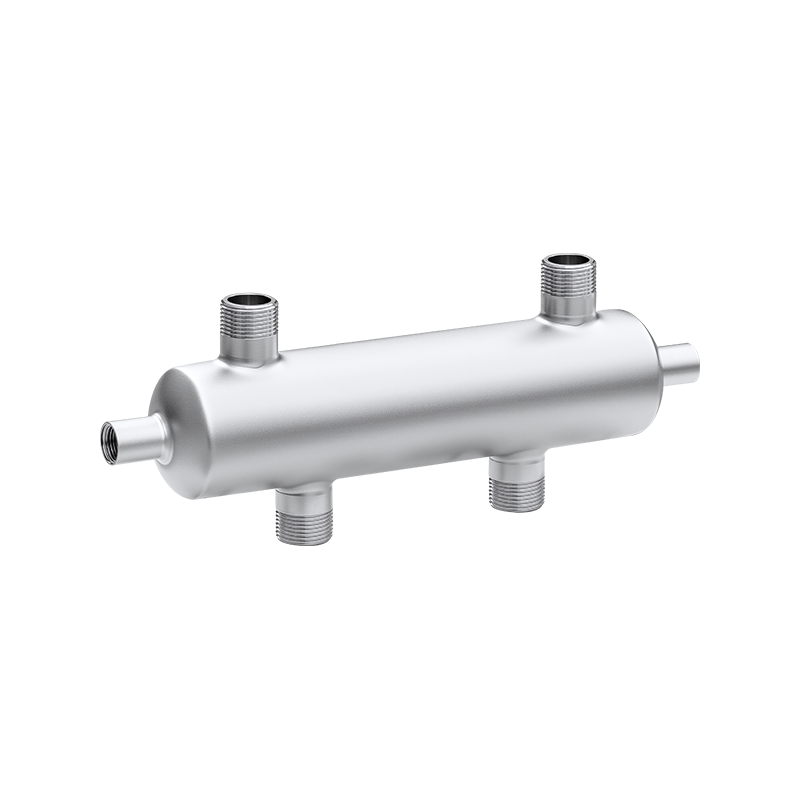

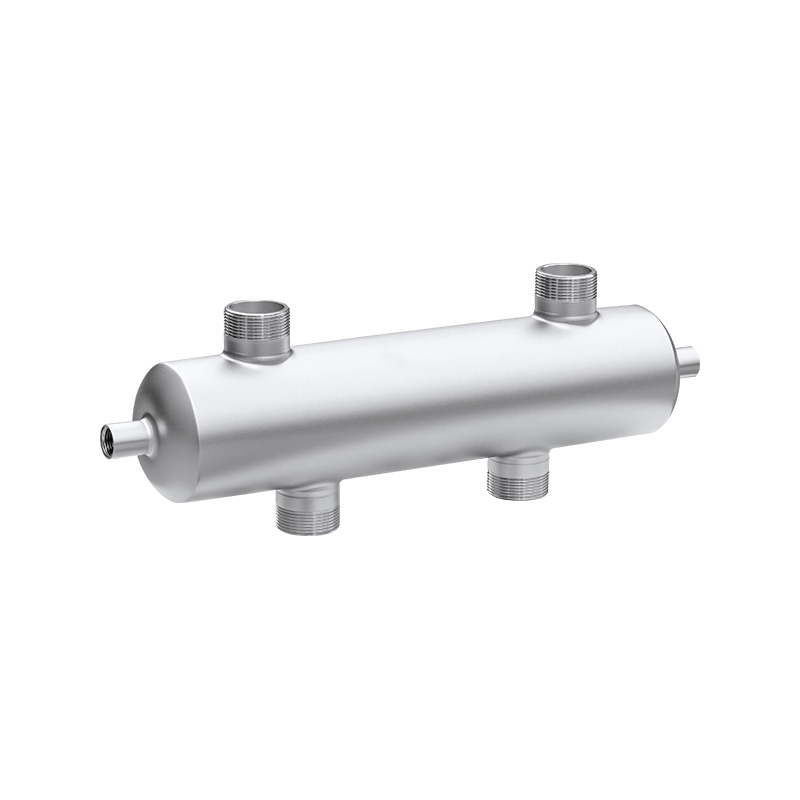

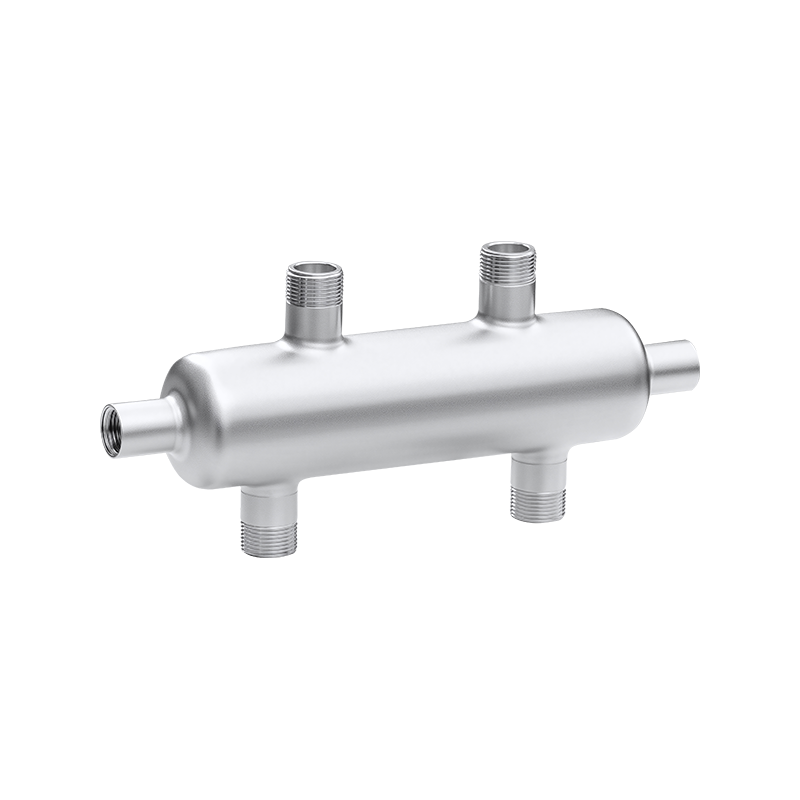

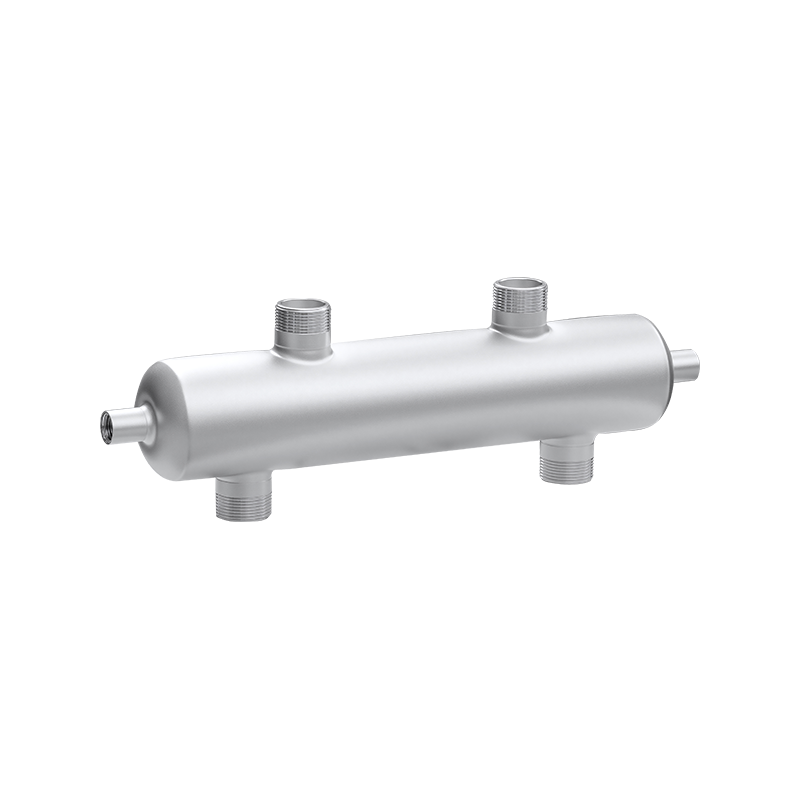

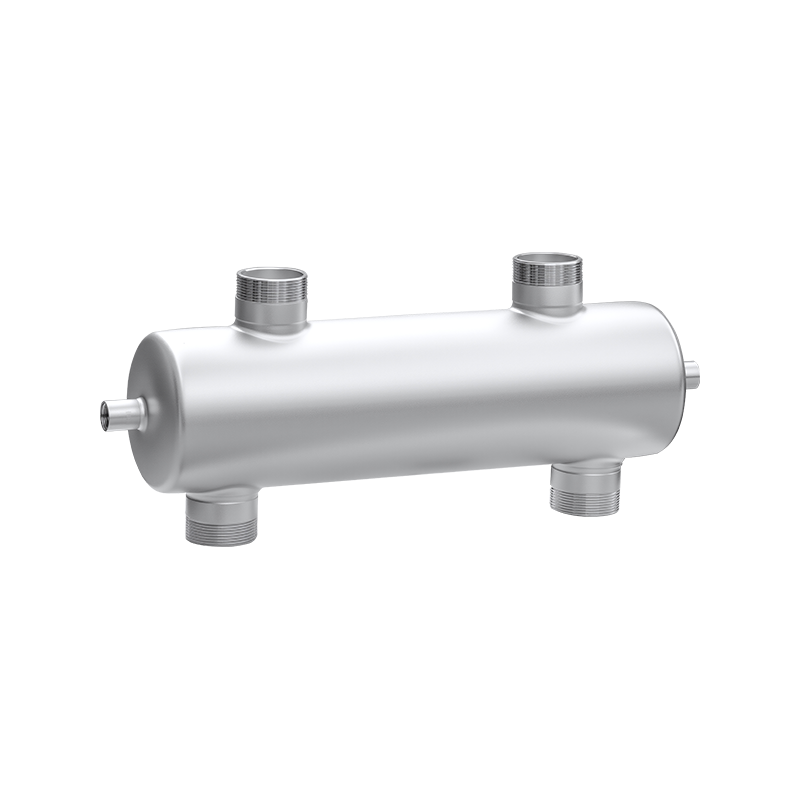

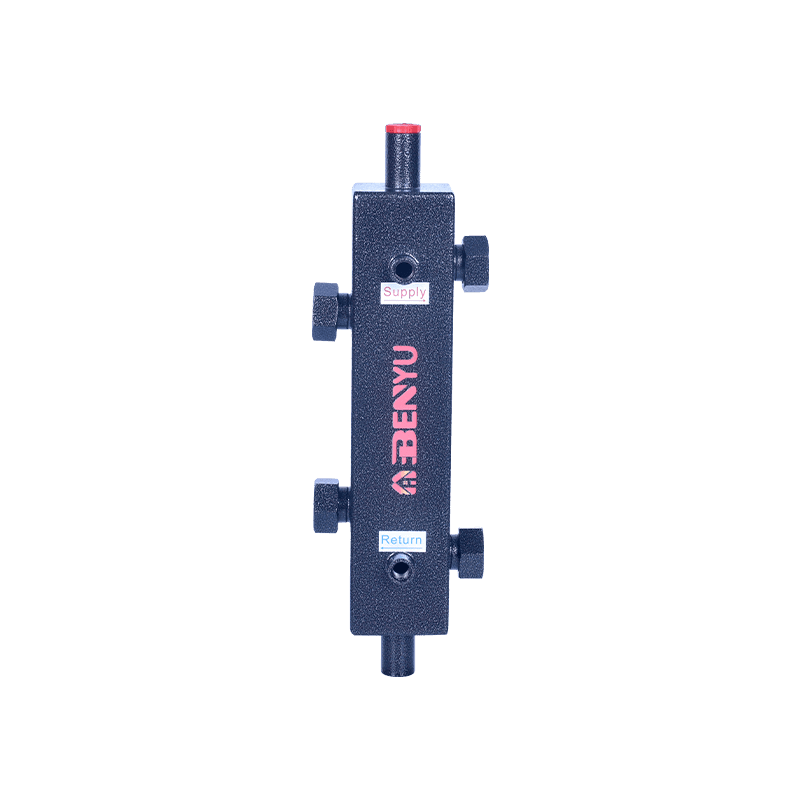

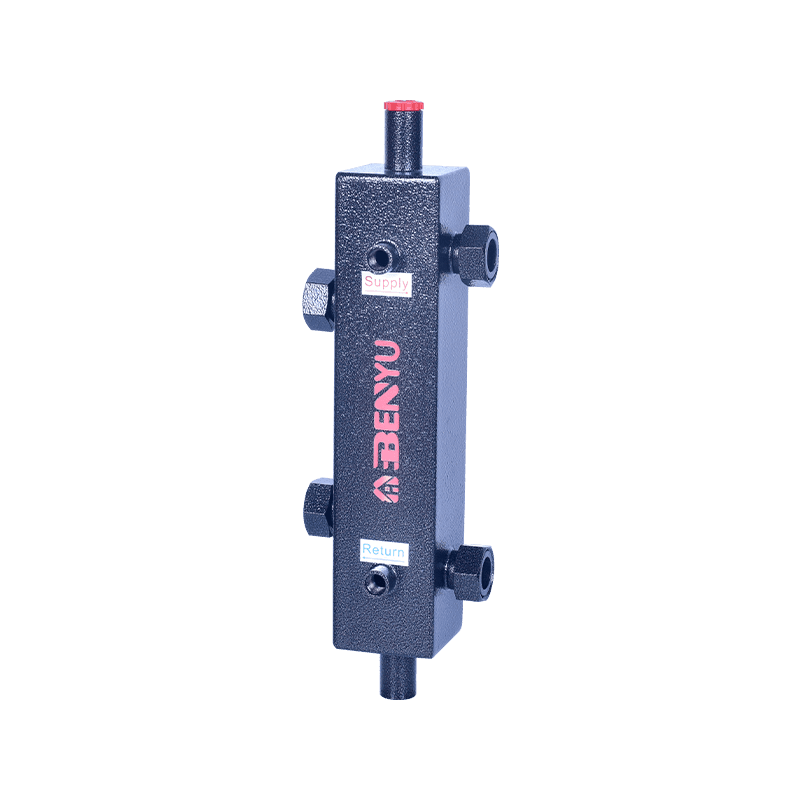

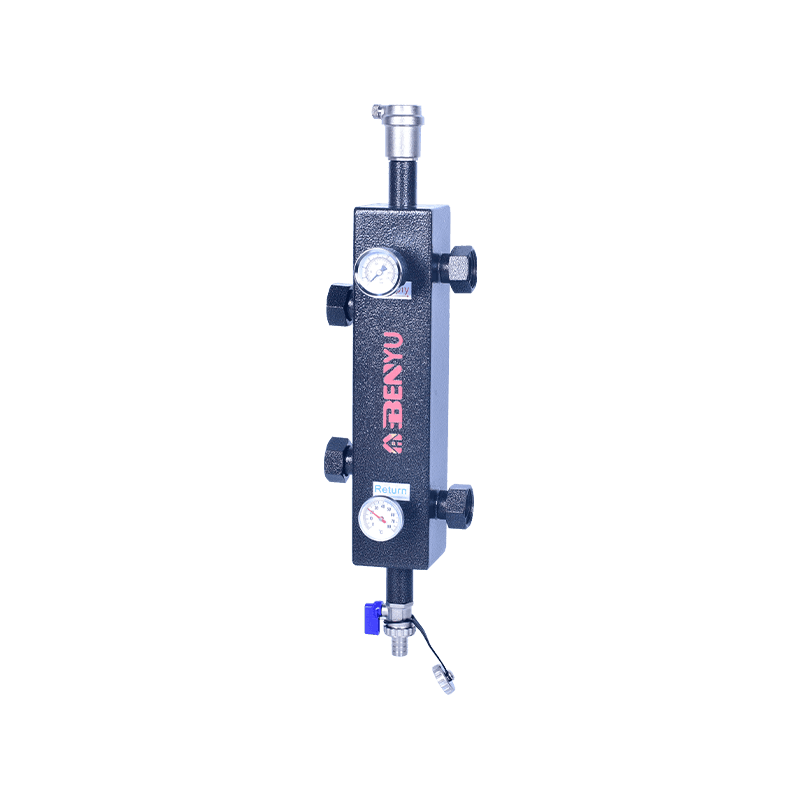

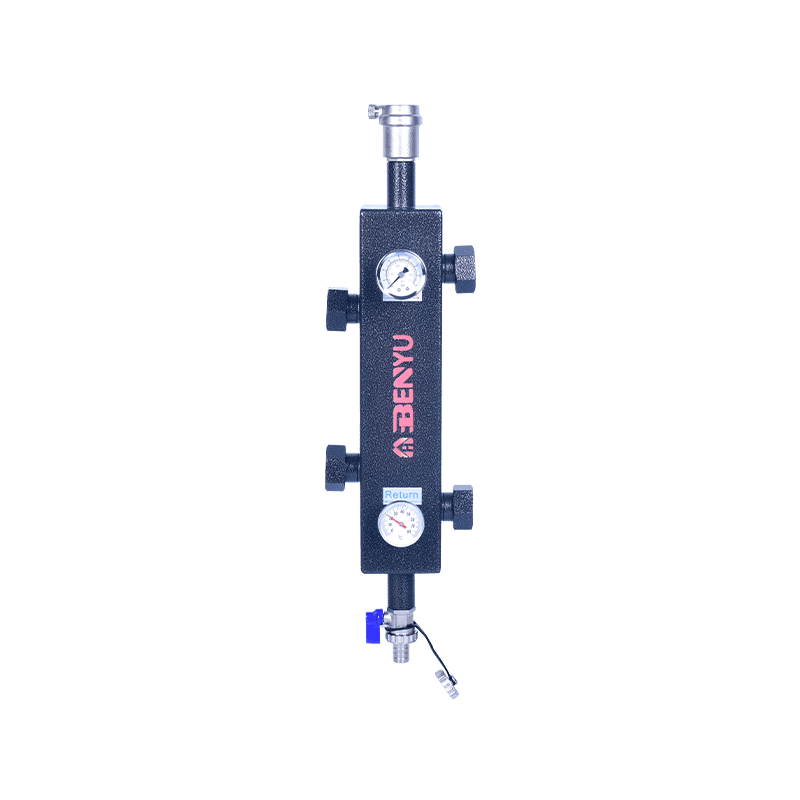

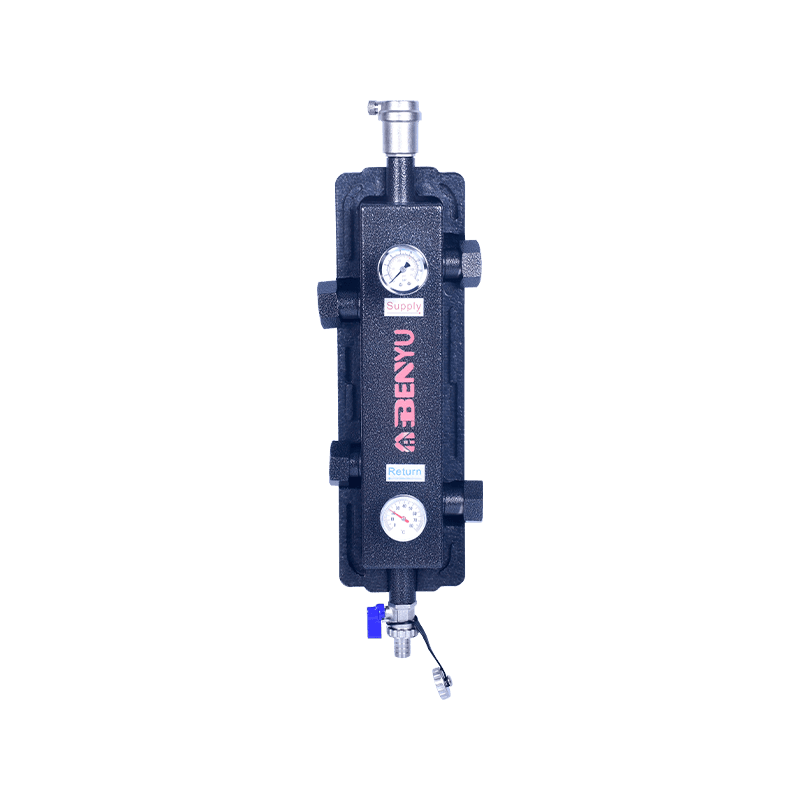

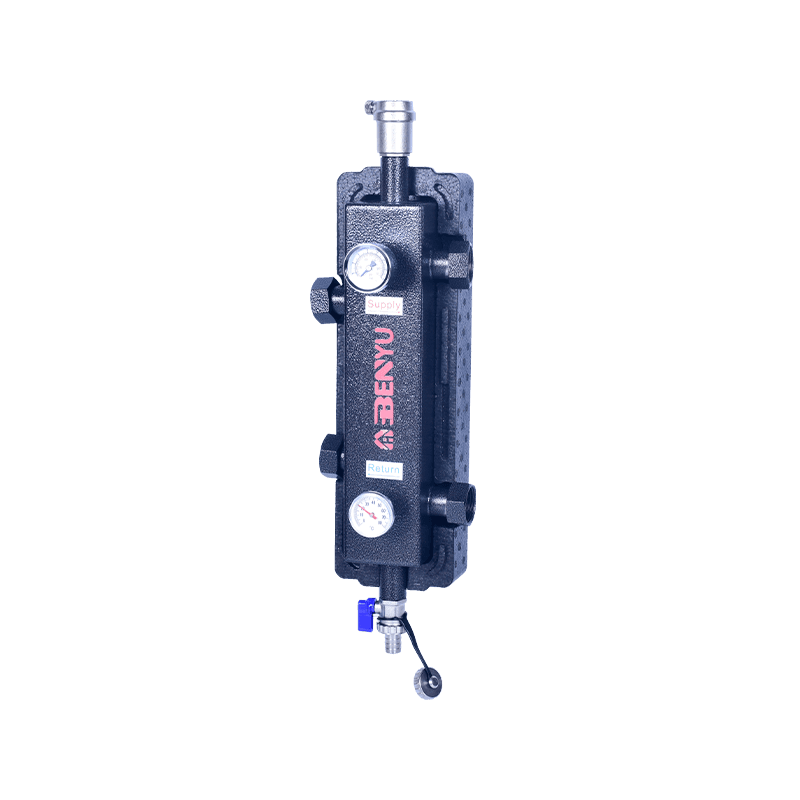

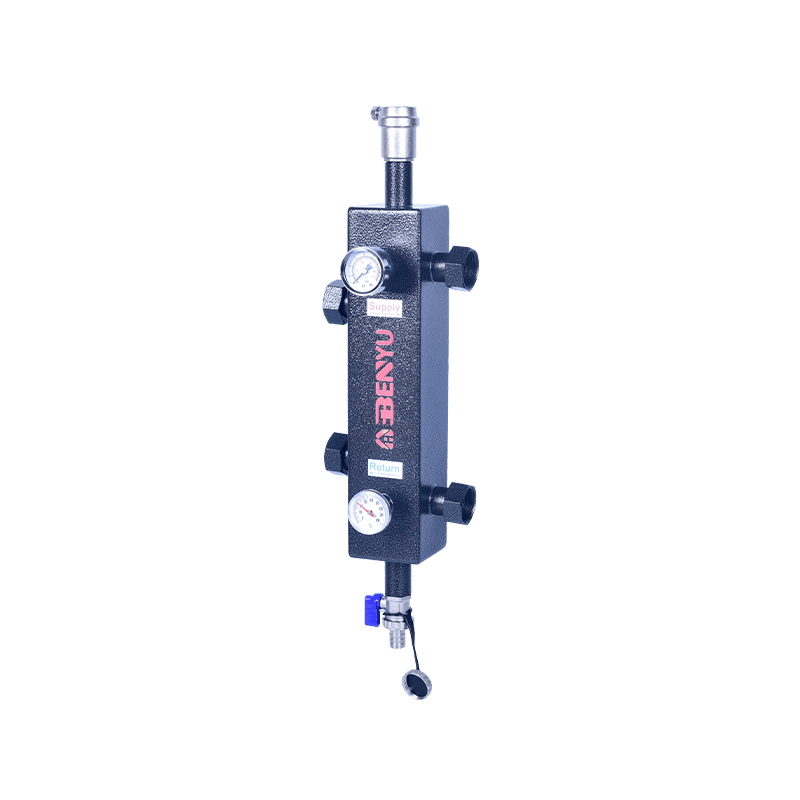

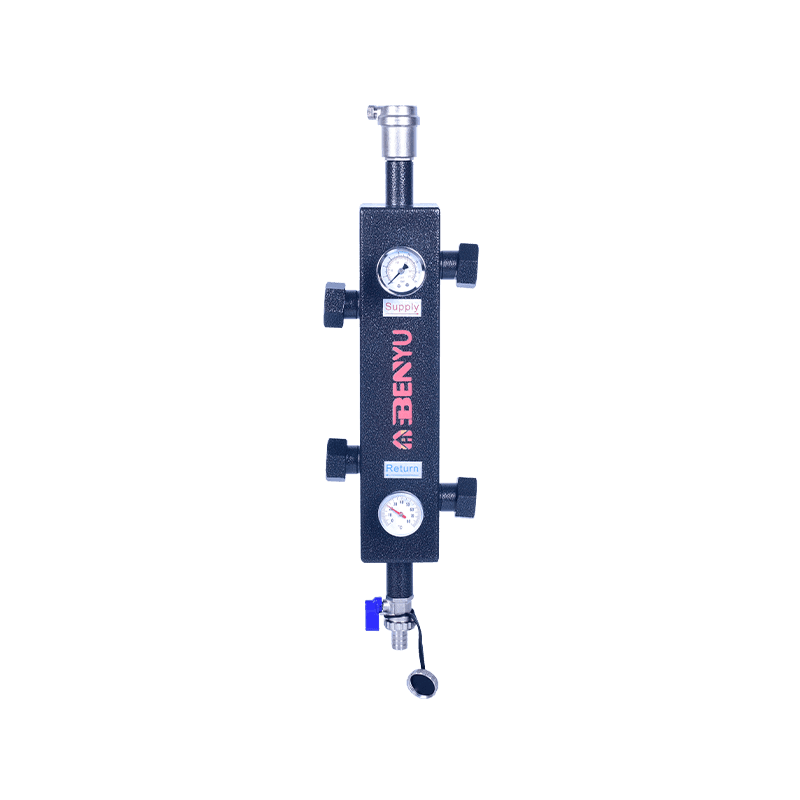

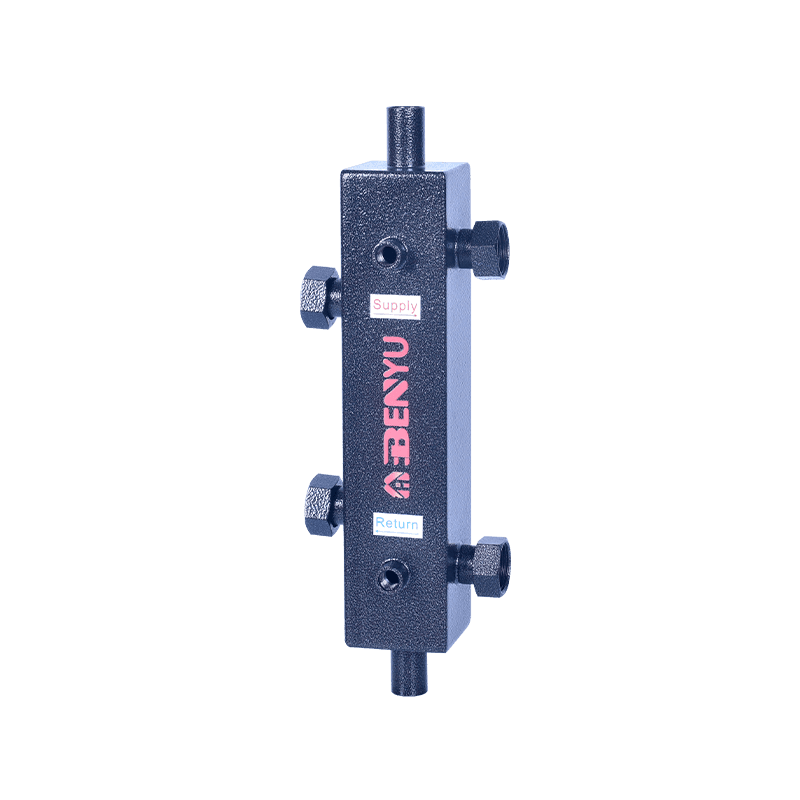

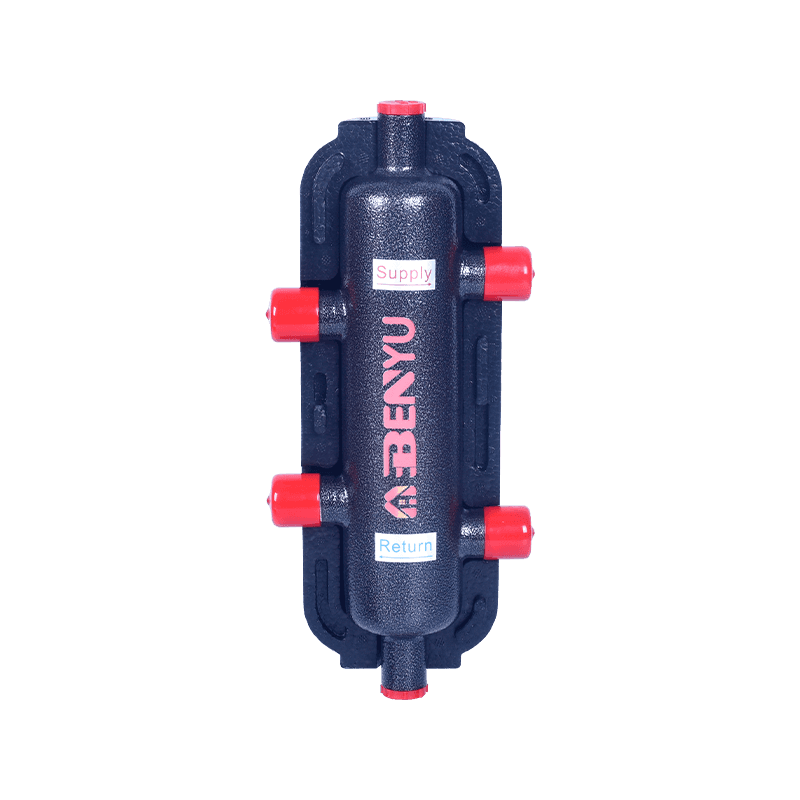

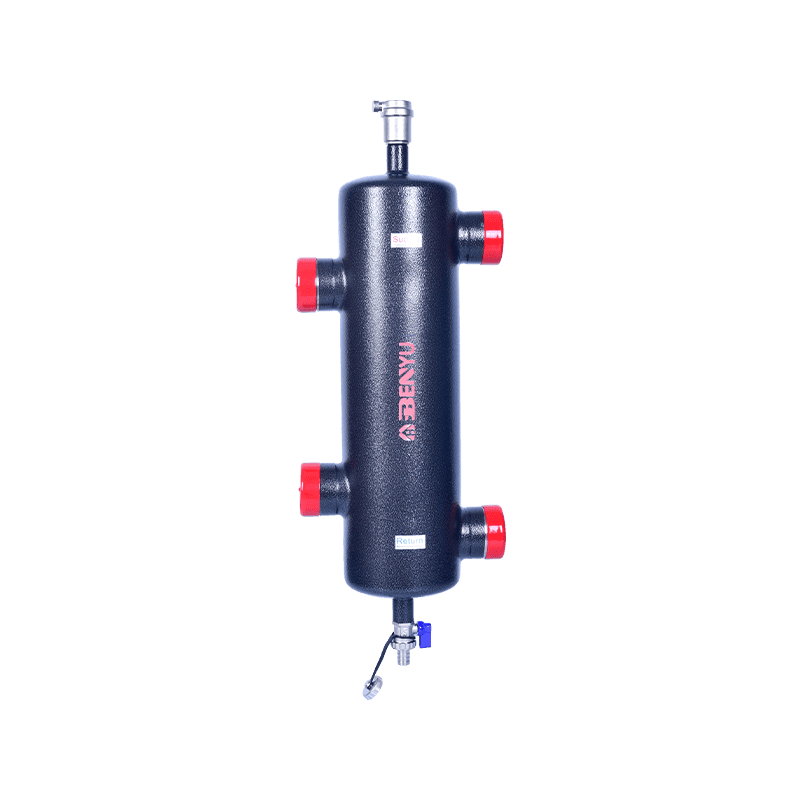

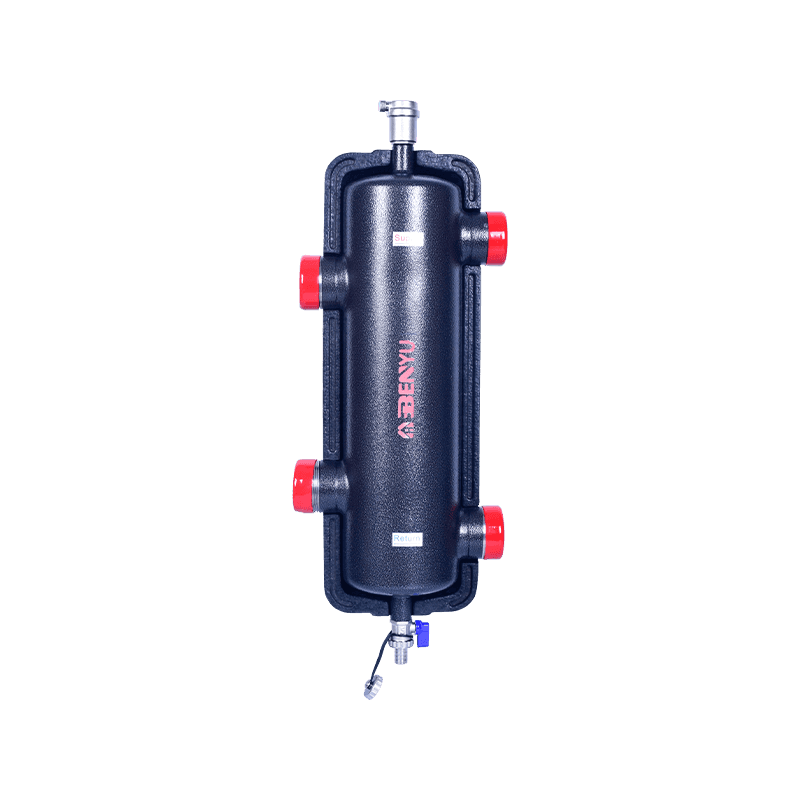

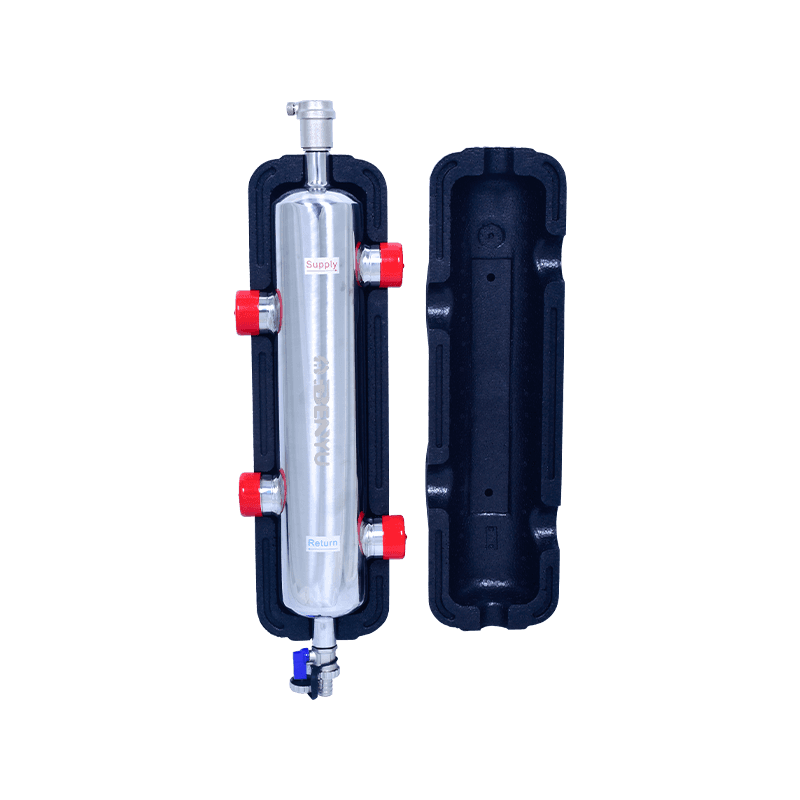

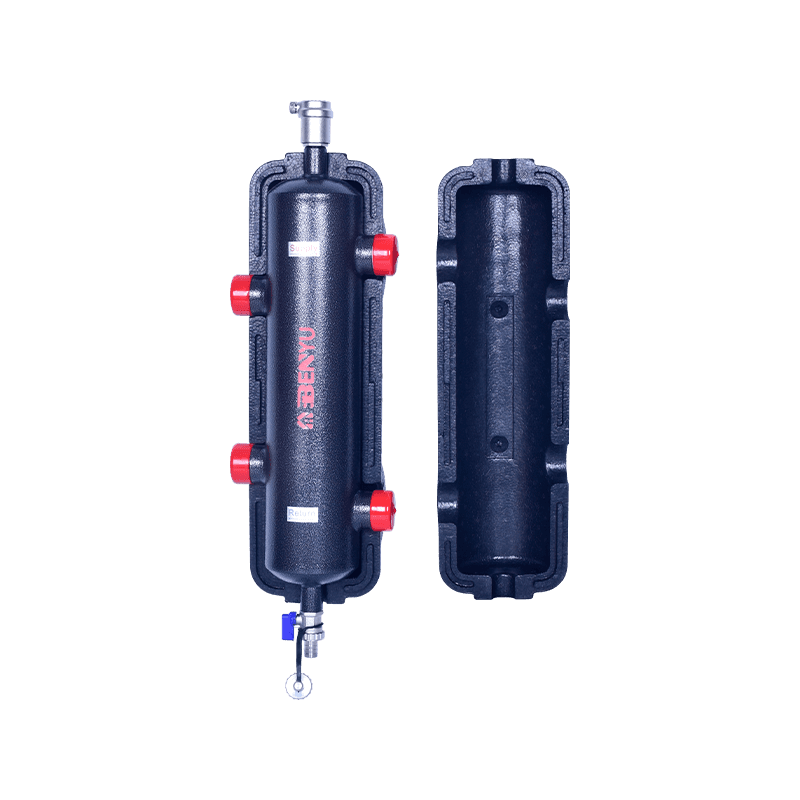

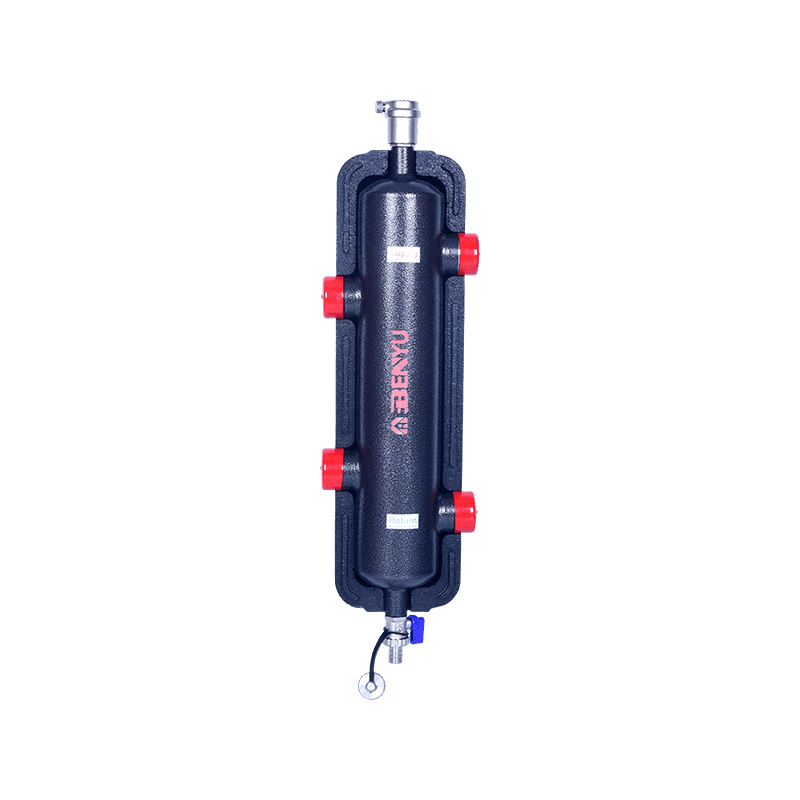

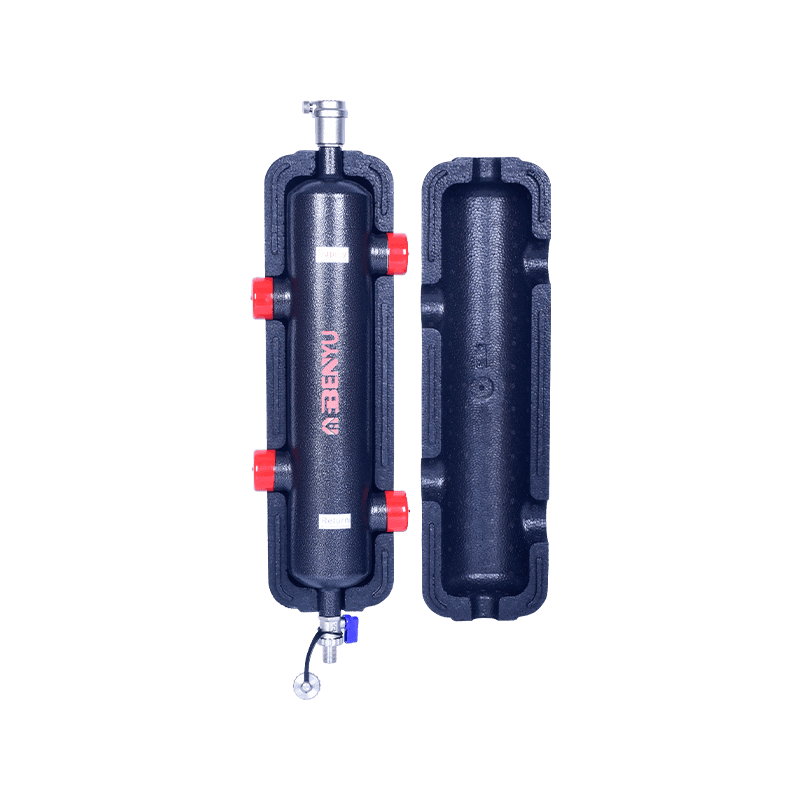

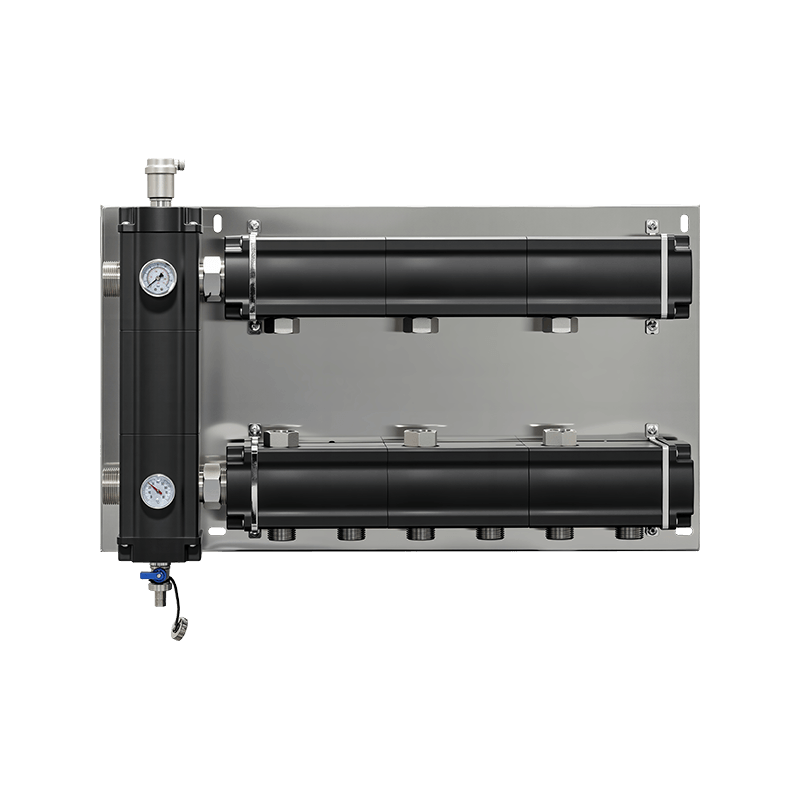

The Decoupling Tank is an essential component in modern heating systems, designed to optimize the performance of underfloor heating and other hydronic heating setups. It serves a critical role in ensuring hydraulic separation between different circuits, allowing for smooth and efficient operation. By stabilizing water temperatures and flow rates, the Decoupling Tank enhances the overall system's efficiency and reliability, making it a valuable addition to any residential or commercial heating system.

Language

Language

2nd Floor, No. 4-6, Zebo Road, Yueqing City

Wenzhou City,Zhejiang Province, China

2nd Floor, No. 4-6, Zebo Road, Yueqing City

Wenzhou City,Zhejiang Province, China